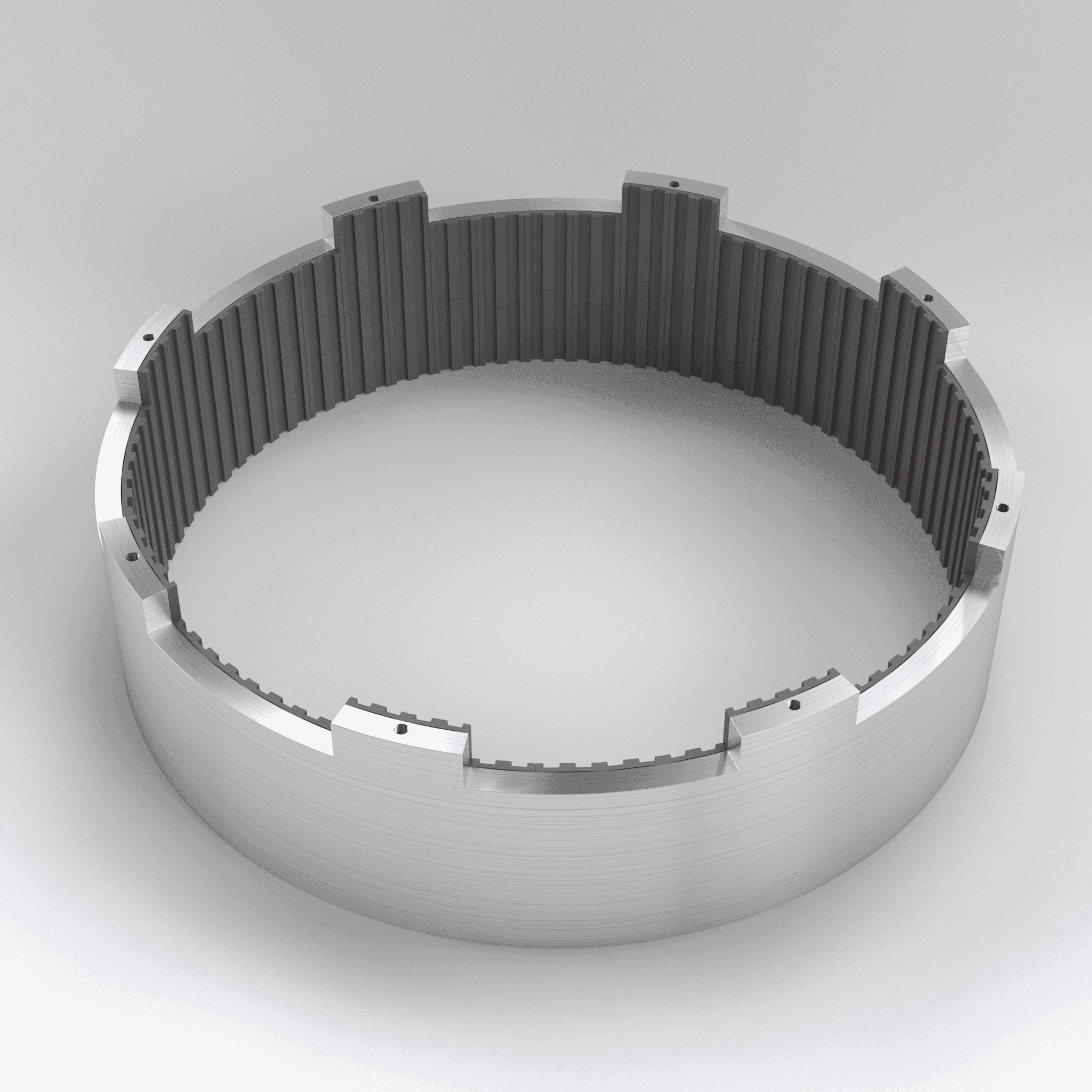

Silicon carbide lined stator mill.

Omegaslate (UK) Ltd.

Engineering wear resistance solutions

OTHER PRODUCTS AND SERVICES

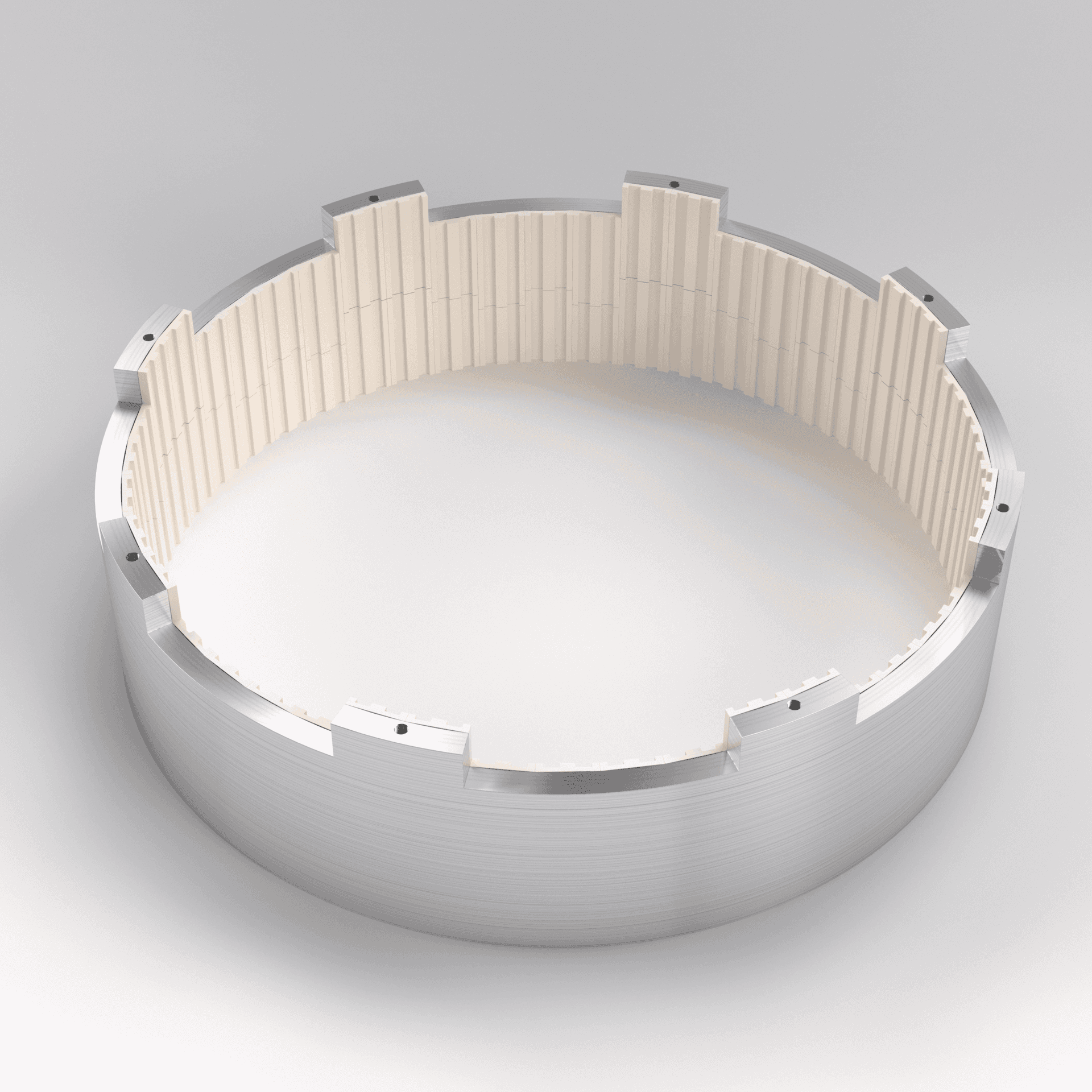

Alumina lined stator mill.

Reaction bonded silicon carbide nozzles for various ambient and high temperature extreme abrasive and corrosive applications.

Spray Nozzles

These are reaction bonded silicon carbide spray nozzle inserts for 1000 degrees Centigrade gas scrubbing applications.

When manufactured from corrosion resistant metal, the nozzles wore out within 2 weeks; the reaction bonded silicon carbide nozzle inserts show no wear or corrosion after many months of operation.

Spray Nozzle

This is a reaction bonded silicon carbide nozzle liner fitted into a titanium housing and is used in the manufacture of titanium dioxide.

The maxium operating temperature would be around 650 degrees centigrade.

Highly Wear Resistant Extruder Barrels and Barrel Liners

Plastics extruder barrels and extruder screws suffer from extreme wear when mineral fillers such as quartz are added to the plastic. Omegaslate uses one of the hardest materials available to dramatically reduce the rate of wear in plastic extruder barrels.

Omegaslate (UK) Ltd.

Unit 206 Foley Industrial Estate

Beauchamp Avenue

Kidderminster, Worcs. U.K.

DY11 7DH

tel: +44 (0)1562 755824

email: info@omegaslate.com

www.omegaslate.com

Omegaslate (UK) Ltd.

proudly sponsors KAFC Under 12s Cobras.

All content is copyright of Omegaslate (UK) Ltd. The copying or reproduction of images/content is strictly prohibited without the consent of Omegaslate (UK) Ltd.

Omegaslate (UK) Ltd. © 2024